Product Center

Quality Inspection for Aluminium Composite Panel Fabrication - ZINC FIREPROOF COMPOSITE PANEL – BOTEC

Quality Inspection for Aluminium Composite Panel Fabrication - ZINC FIREPROOF COMPOSITE PANEL – BOTEC Detail:

Advantages

Surface materials and thermal insulation materials are non-combustible materials, which can fully meet the requirements of fire protection regulations for prefabricated houses. Various studies have shown that it has been widely used in foreign countries for more than 40 years. The shelf life of color steel plates treated with special coatings is 10-15 years, and later Spray anti-corrosion paint every 10 years, and the life of the prefab board can reach more than 35 years. The clear lines of the beautiful profiled color steel plate are as many as dozens of colors, which can meet the needs of any style of prefab buildings and achieve satisfactory results. It has good flatness and rigidity with large size panels, and also has strong dimensional stability, we can solve complex shapes.

Due to the characteristics of copper, copper profiles have good resistance, and it is not easy to deform and destroy under the influence of external forces during application. With this advantageous feature, this type of copper material can perform very well in long-term applications.

Relying on good ductility and plasticity, copper profiles can use this feature to resist the negative impact of external forces and avoid being affected by external forces. This type of copper material can show stable and firm application effects.

With the characteristics of high compressive strength and good resistance, the overall structure of the copper profile must be very appropriate. Such a structure can be used stably and reliably, and always play its role normally.

Specification

|

Panel width |

980mm, 1000mm |

|

Panel thickness |

3mm, 4mm, 5mm, 6mm |

|

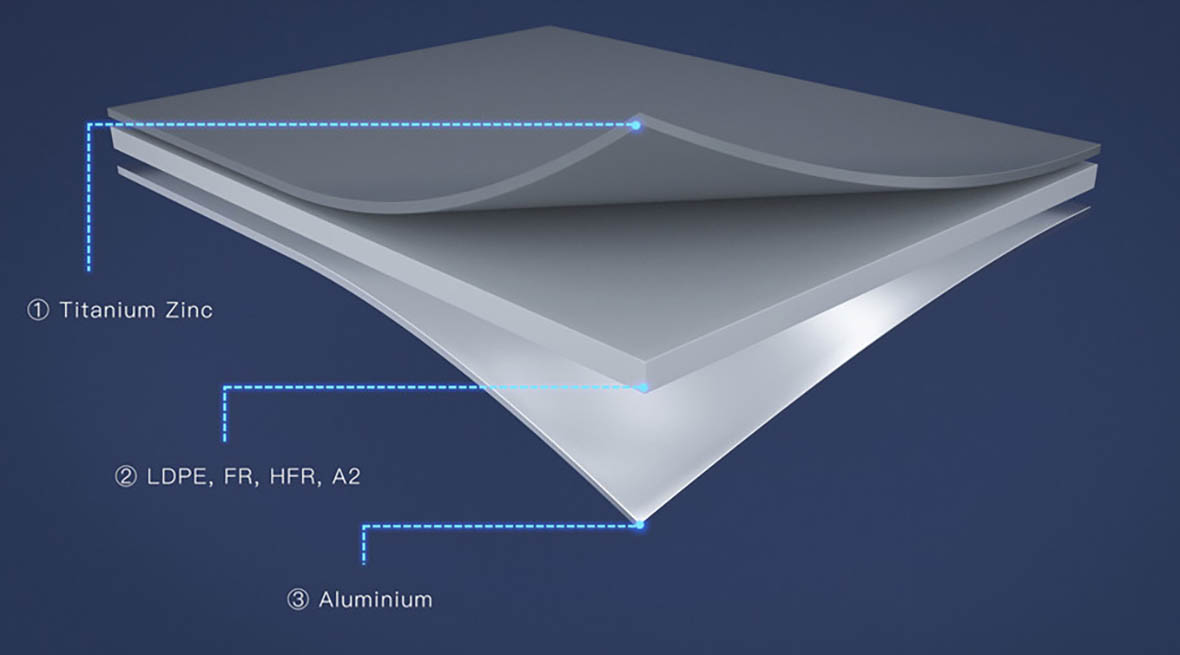

Zinc thickness |

0.5mm, 0.7mm |

|

Panel length |

2440mm, 3200mm (up to 5000mm) |

Product detail pictures:

Related Product Guide:

Our growth depends on the superior equipment ,exceptional talents and continuously strengthened technology forces for Quality Inspection for Aluminium Composite Panel Fabrication - ZINC FIREPROOF COMPOSITE PANEL – BOTEC , The product will supply to all over the world, such as: Kyrgyzstan, Germany, Southampton, Welcome to visit our company, factory and our showroom where displays various hair products that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to provide you the best service. Please contact us if you need more information. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation.

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.