Product Center

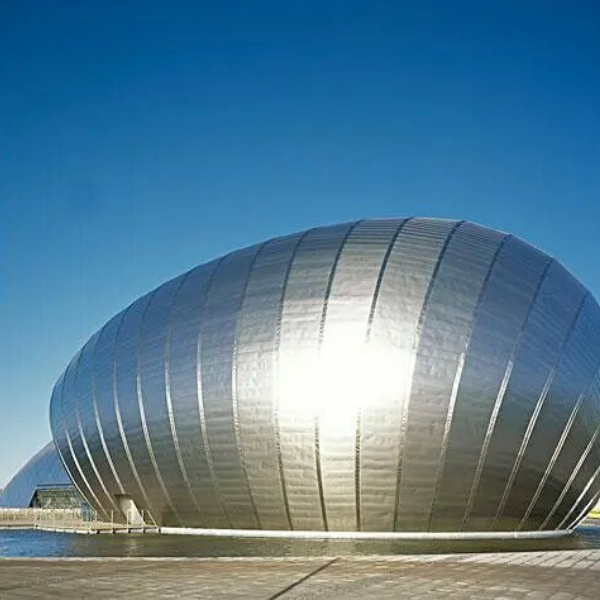

OEM/ODM Supplier Composite Panel Weight - TITANIZE FIREPROOF MENTAL COMPOSITE PANEL – BOTEC

OEM/ODM Supplier Composite Panel Weight - TITANIZE FIREPROOF MENTAL COMPOSITE PANEL – BOTEC Detail:

Product Description

Titanium is an important structural metal with high strength, good corrosion resistance and high heat resistance, and is widely used in various fields. Many countries in the world have recognized the importance of titanium alloy materials, and have successively carried out research and development on them, and have been put into practical applications. The development of my country’s titanium industry is relatively mature internationally.

Advantages

The surface of titanium metal will be continuously oxidized to form a titanium oxide film, which can inhibit the growth of bacteria, so that the titanium daily necessities have good antibacterial properties. Compared with traditional containers such as stainless steel, glass, and casserole, titanium containers have better fresh-keeping performance when holding beverages such as juice, traditional Chinese medicine, and milk.

Titanium metal has excellent corrosion resistance, even aqua regia cannot corrode it. It is precisely because of this feature that the Jiaolong deep-sea probe also uses titanium metal, which can be placed in the deep sea for a long time without being corroded. It is also because the titanium metal is strong and corrosion-resistant, so it can be recycled, and it is an environmentally friendly material in the true sense.

Titanium can withstand high temperatures without deformation, so it is also widely used in the aerospace field. The melting point of titanium is as high as 1668 °C, and it will not be damaged in long-term use at a high temperature of 600 °C. Water glasses made of titanium can be directly heated without damage.

The density of high-titanium metal is 4.51g/cm, which has high specific strength and light weight. For bicycles with the same volume and strength, the titanium frame is lighter. This is of great significance for civilian products, and can be made into lighter pots and outdoor utensils.

Product detail pictures:

Related Product Guide:

The very rich projects management experiences and one to one service model make the high importance of business communication and our easy understanding of your expectations for OEM/ODM Supplier Composite Panel Weight - TITANIZE FIREPROOF MENTAL COMPOSITE PANEL – BOTEC , The product will supply to all over the world, such as: Albania, Mexico, Greek, Our professional engineering group will always be ready to serve you for consultation and feedback. We are able to also offer you with absolutely free samples to meet your requirements. Finest efforts will likely be produced to give you the ideal service and goods. For anyone who is thinking about our company and merchandise, please contact us by sending us emails or contact us quickly. As a way to know our merchandise and firm. lot more, you can come to our factory to find out it. We'll always welcome guests from all over the world to our business to build company relations with us. Please feel free to get in touch with us for business and we believe we are going to share the top trading practical experience with all our merchants.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.