Product Center

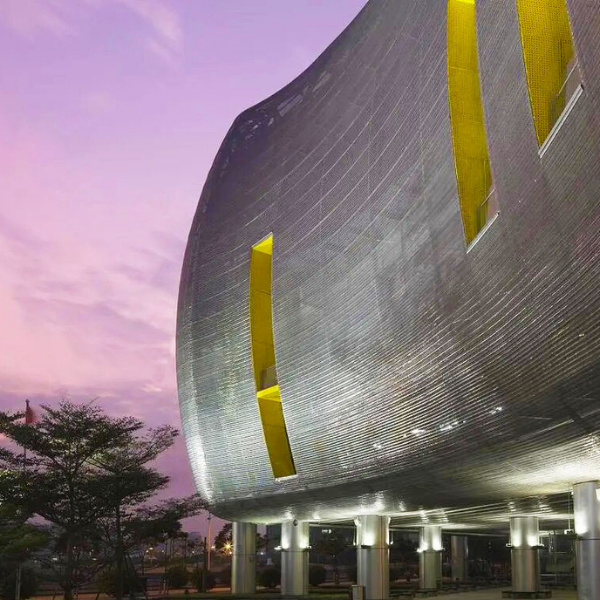

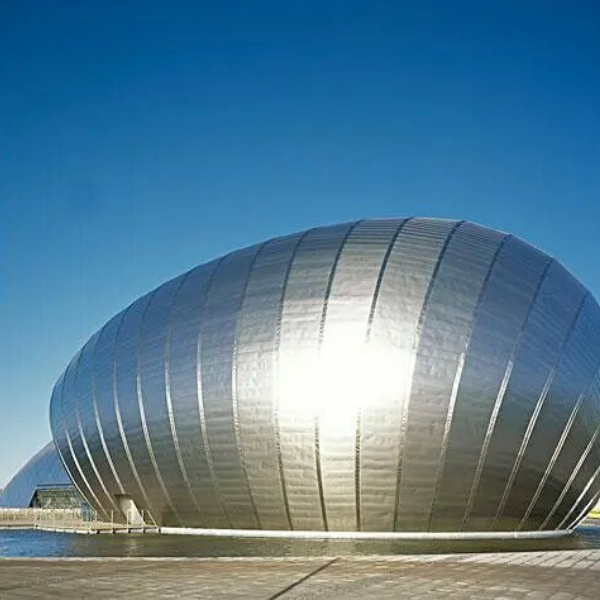

OEM manufacturer Aluminium Composite Panel Building Design - TITANIZE FIREPROOF MENTAL COMPOSITE PANEL – BOTEC

OEM manufacturer Aluminium Composite Panel Building Design - TITANIZE FIREPROOF MENTAL COMPOSITE PANEL – BOTEC Detail:

Product Description

Titanium is an important structural metal with high strength, good corrosion resistance and high heat resistance, and is widely used in various fields. Many countries in the world have recognized the importance of titanium alloy materials, and have successively carried out research and development on them, and have been put into practical applications. The development of my country’s titanium industry is relatively mature internationally.

Advantages

The surface of titanium metal will be continuously oxidized to form a titanium oxide film, which can inhibit the growth of bacteria, so that the titanium daily necessities have good antibacterial properties. Compared with traditional containers such as stainless steel, glass, and casserole, titanium containers have better fresh-keeping performance when holding beverages such as juice, traditional Chinese medicine, and milk.

Titanium metal has excellent corrosion resistance, even aqua regia cannot corrode it. It is precisely because of this feature that the Jiaolong deep-sea probe also uses titanium metal, which can be placed in the deep sea for a long time without being corroded. It is also because the titanium metal is strong and corrosion-resistant, so it can be recycled, and it is an environmentally friendly material in the true sense.

Titanium can withstand high temperatures without deformation, so it is also widely used in the aerospace field. The melting point of titanium is as high as 1668 °C, and it will not be damaged in long-term use at a high temperature of 600 °C. Water glasses made of titanium can be directly heated without damage.

The density of high-titanium metal is 4.51g/cm, which has high specific strength and light weight. For bicycles with the same volume and strength, the titanium frame is lighter. This is of great significance for civilian products, and can be made into lighter pots and outdoor utensils.

Product detail pictures:

Related Product Guide:

Our intention is usually to satisfy our buyers by offering golden provider, great rate and good quality for OEM manufacturer Aluminium Composite Panel Building Design - TITANIZE FIREPROOF MENTAL COMPOSITE PANEL – BOTEC , The product will supply to all over the world, such as: Munich, Zimbabwe, Morocco, We now have to continue to uphold the "quality, detailed, efficient" business philosophy of "honest, responsible, innovative"spirit of service, abide by the contract and abide by reputation, first-class goods and improve service welcome overseas customers patrons.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!