In the past more than 20 years of successful trial production of thermal composite production line, the industry of metal composite materials in China has grown from small to large, from weak to strong, and promoted the green development of the industry by innovation drive, and gained remarkable development achievements. The industry has formed a complete and advanced industrial development chain covering research and development, production, application and so on. China has also become the producer, consumer and exporter of large metal composite materials in the world.

Green proposition supports industry development

Green development is an important theme of the "13th Five-Year Plan" development of building materials industry, which provides a new support point and development path for building materials industry to achieve a higher level of development. As an important basic raw material industry of the national economy, the building materials industry not only has the important task of energy conservation, emission reduction and comprehensive utilization of resources in its own development, but also shoulders the important mission of providing material support for the construction of ecological civilization.

Metal composite material industry in the process of implementation of green manufacturing, gradually realize the product whole life cycle of the importance of environmental impact, full of green manufacturing system throughout from natural resources, raw materials procurement, product manufacturing, factory, the whole industry chain enterprises, involved in green products, green enterprises, green plant, green parks, green supply chain, and many other aspects, Among them, the production process and the technology of energy-saving and environmental protection equipment are important. Combining with the characteristics of metal composite material industry emissions and exhaust emission control standards, the industry a series of development and application of green manufacturing technology, energy saving and emission reduction of the processing of waste gas, heat in the process of its processing, in addition to its operation need excess heat through the heat back into the oven for reuse, achieved the purpose of energy conservation and emissions reduction. Coating line at the same time, the catalytic combustion of waste heat utilization, baking coating line heating, composite process, extrusion molding machine heating process, extrusion molding machine screw extrusion and other green technology widespread application in manufacturing enterprises, the extensive mode of growth, changed the industry formed the intensive enterprises today, the lean production mode, realize the transformation and upgrading of metal composite decorative materials industry and sustainable development.

Standard first revitalize the industrial chain

In the fierce competition at home and abroad, new technologies and new products constantly emerge, but without the guidance of advanced standards, it is difficult to get out of the quagmire of low-level competition. Technical standards should go ahead of products, not only in the end of the industrial chain, all nodes in the industrial chain should adopt the strategy of "guiding technological progress with technical standards, improving product quality with technical standards, and winning the high-end market with technical standards". Only in this way can the vitality of the enterprise be ensured; Only in this way, ability revitalizes whole industrial chain.

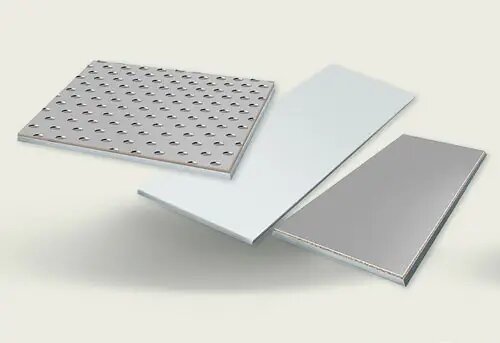

Metal composite material industry adhere to the standard leading industry development, formed a set with independent intellectual property rights of "aluminum-plastic composite panels production and technology of China," by imports, introduced the production technology and equipment, gradually transformed into production technology exporter, aluminum-plastic composite panels complete sets of production equipment have been exported to more than a dozen countries and regions of the world. China's aluminum-plastic panel industry has made remarkable achievements, and has developed into the world's largest producer of aluminum-plastic panels with an annual capacity of more than 400 million square meters. It is exported to more than 120 countries and regions, accounting for more than 90% of the world's import and export trade volume of aluminum-plastic panels. It has realized a complete industrial chain integrating production equipment, processing and application equipment, raw material supporting, product production, technology research and development, trade and application. In the process of the development of the industry, the standard in the field of metal and metal composite material system is increasingly perfect, the product covers the aluminum-plastic composite panels, aluminum veneer, condole roof, color steel panel, aluminum honeycomb composite panels, aluminum composite panels, corrugated core copper plastic composite panels, titanium zinc composite panels and metal decoration insulation panel products such as almost all of the products, It plays an important role in promoting technical progress and application of metal composite products in our country and promoting healthy development of the whole industry. Most of these standards belong to the domestic and foreign countries for the first time, and we can say that the product standards of metal composite materials in China are leading the development of metal composite materials industry in the world.

Equipment manufacturing industry continues to lead

The manufacturing industry is the main body of the national economy, is the foundation of the country, the instrument of national rejuvenation, the foundation of strong country. To build competitive manufacturing industry is the only way for China to enhance comprehensive national strength, ensure safety and construct world power. Since the reform and opening up, Chinese manufacturing industry has developed rapidly, and the metal composite materials industry has a complete and independent industrial system, which promotes the industrialization and modernization of the industry strongly. At present, the new round of scientific and technological revolution and industrial transformation and accelerating the transformation of economic development mode to form a historic significance, industrial division of labor pattern is reshaping. The metal composite material industry has grasped this important historical opportunity and, in accordance with the "four comprehensive" strategic layout requirements, implemented the strategy of manufacturing power, strengthened overall planning and forward-looking deployment, and made efforts to become a manufacturing power leading the development of the world manufacturing industry.

In the development of equipment and technology, many enterprises have found a way to meet their own development in the transformation and upgrading. For the equipment manufacturing industry, improving energy efficiency, equipment level and reducing labor input is one of the keys to transformation and upgrading. The overall technical level of manufacturing equipment is reflected in automation, high-speed, efficient, stable, precision, energy saving, intelligent and networking. Relying on the combination of scientific and technological innovation and the development mode of "fine, specialized, strong, special and new", the product structure is adjusted. In the metal composite material industry, there have emerged many world-class enterprises in equipment technology and developed a series of products with a leading position.

In the process of realizing the transformation from a manufacturing power to a manufacturing power, intelligence is undoubtedly an important direction. Intelligent manufacturing involves network technology, factory floor, product logistics, product design services and other aspects, which is a long and lengthy realization process. It is gratifying that many enterprises have come out of a business model of data-driven production and realized personalized customization by means of industrialization, which has boosted the transformation and upgrading of metal composite decorative materials industry from traditional manufacturing to intelligent manufacturing.

Product application close to people's life

Along with the continuous economic development of China, the urban construction is changing rapidly. Metal composite decorative materials with its light weight, high specific strength, rich decorative effect and other advantages, the amount of more and more large, application areas are also more and more. In terms of product innovation, from the traditional aluminum plastic panel, aluminum veneer, color steel panel, aluminum honeycomb panel, aluminum profile, to metal decorative insulation panel, aluminum foam panel, titanium zinc composite panel, copper plastic composite panel, aluminum corrugated panel, visor, etc., metal composite decorative materials toward high performance, multi-purpose direction. In terms of application, we used metal composite materials used in outdoor, and the modern flavor and gorgeous texture of metal products can also be highlighted in interior decoration, such as metal integrated ceiling and integrated wall. The lightweight, formaldehyde-free, high temperature resistance and corrosion resistance of materials are also in line with the requirements of material selection for interior decoration. The diversification, multi-function and multi-purpose of metal composite decorative materials have also attracted the attention of other industries, such as color TV, automobile, ship, aerospace, etc., in some of the key parts are selected. Metal composite decorative materials have become an indispensable factor in the national economic construction. In the future, driven by the development of science and technology, the application scope of metal composite materials will be wider and closer to people's lives.

Post time: Aug-09-2022