Product Center

Factory making Fire Rated Aluminum Composite Panel - FR A2 ALUMINUM COMPOSITE PANEL – BOTEC

Factory making Fire Rated Aluminum Composite Panel - FR A2 ALUMINUM COMPOSITE PANEL – BOTEC Detail:

Product Description

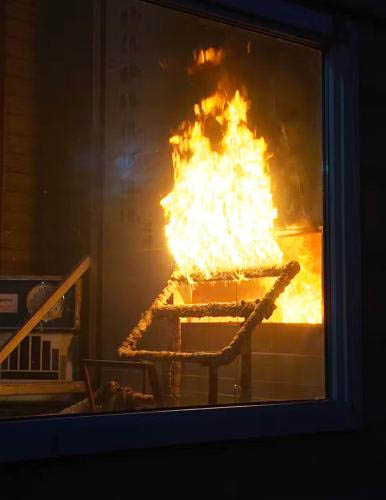

NFPA285 Test

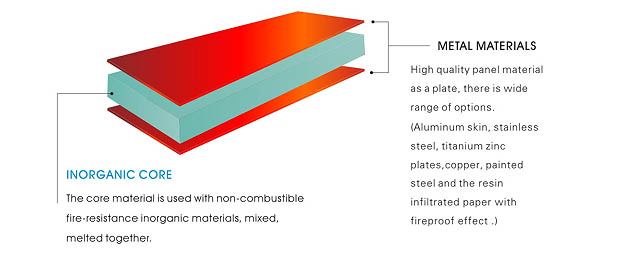

Alubotec® Aluminium Composites (ACP) are made by continuously bonding two thin aluminium skins on both sides of mineral filled flame retardant thermoplastic core. The aluminium surfaces are pre-treated and painted with various paints before lamination. We also offer Metal Composites (MCM), with copper, zinc, stainless steel or titanium skins bonded to the same core with a special finish. Both Alubotec® ACP and MCM provide the rigidity of thick sheet metal in a lightweight composite.

Alubotec ACP can be made with ordinary woodworking or metalworking tools, no special tools are required. Cutting, slotting, punching, drilling, bending, rolling, and many other manufacturing techniques can easily create an almost infinite variety of complex forms and shapes. A2 grade aluminum composite panels are often used in public buildings, such as office buildings, commercial real estate, supermarket chains, hotels, airports, subway transportation, hospitals, art galleries, art galleries and other places with high fire resistance requirements and crowd intensive.

Compared with Solid Aluminum, Alubotec A2 FR has low price, light weight, high strength, smooth surface, good coating quality, good insulation ,and easy processing. It is the replacement of traditional products-solid aluminum, fits for high required fire walls and indoor and outdoor decoration.

Specification

|

Panel width |

1220mm |

|

Panel thickness |

3mm, 4mm, 5mm |

|

Panel length |

2440mm (length up to 6000mm) |

Product detail pictures:

Related Product Guide:

Fast and fantastic quotations, informed advisers to help you choose the correct products that suits all your needs, a short manufacturing time, responsible good quality control and distinct companies for paying and shipping affairs for Factory making Fire Rated Aluminum Composite Panel - FR A2 ALUMINUM COMPOSITE PANEL – BOTEC , The product will supply to all over the world, such as: Peru, Johor, Sheffield, Each product is carefully made, it will make you satisfied. Our products in the production process have got strictly monitored, because it is only to provide you the best quality, we will feel confident. High production costs but low prices for our long-term cooperation. You can have a variety choices and the value of all types are same reliable. If you have any question, do not hesitate to ask us.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.